Permian Basin

Permian Basin

Permian Basin Animation | John Perez Graphics – Federal Copyright # PA 2-121-150

The Permian Basin covers an area 250 miles wide and 300 miles long across west Texas and southeastern New Mexico. It has been the most active oil play in the country with companies aggressively acquiring new acreage across the region. With new drilling and reservoir optimization techniques, longer laterals have become common requiring larger, contiguous blocks of acreage.

Mineral leases often include drilling rights from the surface down to the deepest profitable target. Leasing acreage in the Permian has been fast-paced with companies continually trying to expand their holdings across the region. Smaller companies are being bought up by larger competitors as the basin enters a new phase of efficiency driven by technology.

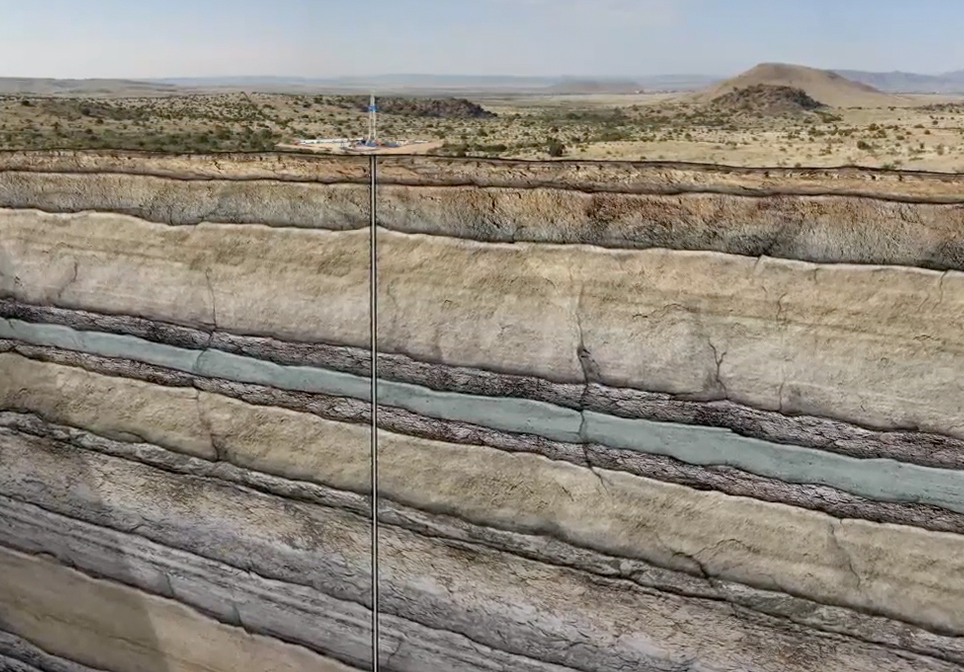

The prize? First class stacked benches or pay zones in both the Delaware and Midland Basins. This offers multiple reservoirs to be drilled horizontally and completed using sophisticated reservoir optimization.

The Delaware and Midland Basins have some common attributes such as lithology and age but differ in other ways. The deeper Delaware has numerous potentially productive stacked pay reservoirs formed from deep water deposits of marine life.

The Central Basin Platform separates the two sub-basins…

…while the shallower but larger Midland Basin acquired its vast petroleum reserves as it was filled east to west by a subaqueous delta system.

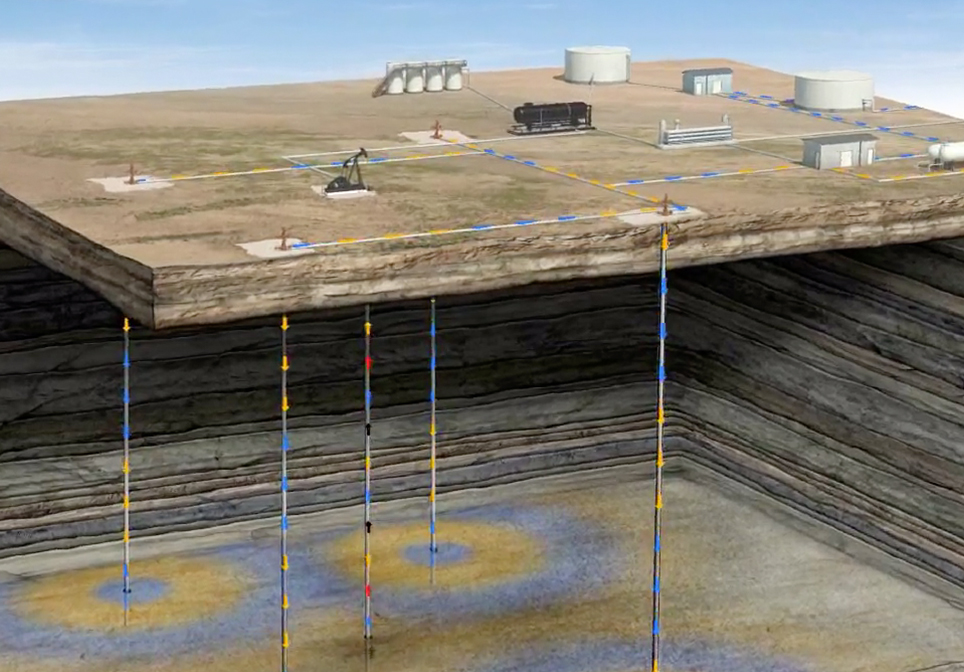

These great Permian reserves no longer need to be unlocked and produced by drilling single wells at a time. By acquiring blocks of acreage to all depths, operators can manufacture the hydrocarbons with a very efficient, multi-well pad development and completions operation. Drilling rigs with walking systems can move from well to well on the multi-well pad removing the rig-up and rig-down time and cost that would be required for individual wells. The wells on the pad can then be simultaneously completed resulting in efficient, full-scale development operation. Oil, gas and water can be moved on and off location through pipes which service the field, lessening road traffic.

Many Permian wells are drilled with rigs which are lined up down the corridor. This is what’s called “mowing the lawn”. Operators are now able to develop these oil and gas resources at scale. The operating expense and capital cost that has been taken out of the operation of this manufactured style concept is tremendous and further improves the economics of the project.

Other GEOART Educational Animations

Multi-stage Vertical Frac

This Multi-Stage Vertical Frac Crude Oil Animation explains and demonstrates how a vertical well is drilled, stimulated and produced from multiple formations to recover hydrocarbons. In this animation, we show a well targeting three sandstone layers. The well is initially drilled to a designated distance below the deepest fresh water source near the surface.

Impact Crater

The 10 biggest impact craters on Earth date back from 35 million to over 2 billion years ago.

When an asteroid or meteorite crashes into the surface of a planet or a moon, a circular depression is formed. To form a true impact crater, this object needs to be traveling at super-fast speeds – many thousands of miles per hour! It immediately vaporizes and creates enormous shockwaves through the ground that melt and recrystallize rock and are one of the most destructive forces in the solar system.

The Chicxulub crater, sometimes referred to as the deadliest location on earth, is buried beneath the Yucatán Peninsula in Mexico. When the Chicxulub asteroid slammed into Earth about 66 million years ago, it obliterated 80 percent of Earth’s species, blasted out a crater about 200 kilometers (124 miles) across and 19 kilometers (12 miles) deep, and signaled an abrupt end to the Cretaceous Period.

CO2 EOR Carbon Dioxide Enhanced Oil Recovery

This CO2 EOR Educational Animation – created by John Perez Graphics & Design, LLC – explains the CO2-EOR process. We travel deep in to the Earth’s subsurface to demonstrate injection, miscibility, WAG, and increased oil production.

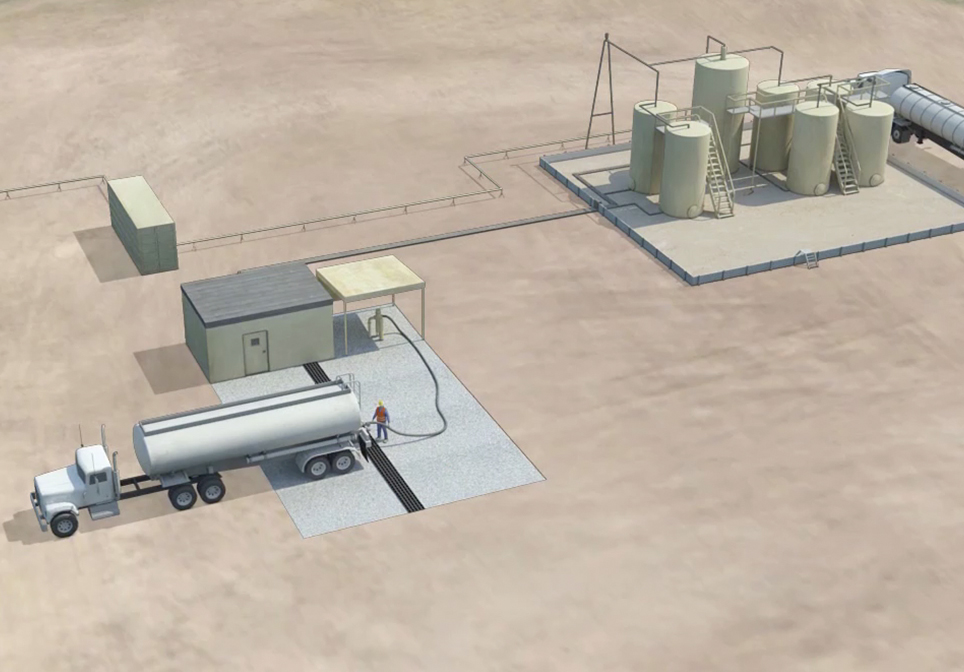

Saltwater Disposal

This Saltwater Disposal Well Animation – created by John Perez Graphics & Design, LLC – explains the steps necessary when disposing of salt water that is produced when drilling an oil or gas well. This geoart animation takes you from the surface facilities, through the various protective casing strings down several thousand feet to the pre-approved formation zone where the salt water will be disposed of. This follows the EPA preferred method for the disposal of produced saltwater in Class II Saltwater Disposal wells.